Cut Costs and Eliminate Risks With Manufacturing Engineering Support

Sometimes the best investment you can make is in someone else’s experience.

When you’re in a design phase for manufacturing, you may be debating whether to bring in manufacturing engineering support. It seems costly at the outset to add another line to your budget. That’s why it’s important to look carefully at the benefits you will see by partnering with specialty engineering services for your manufacturing design.

Take a look at several of the reasons this investment will turn out to be a good one:

Experience: As noted before, it can be hard to put a price on the experience a team of engineers will bring to your design process. They’ve worked with companies like yours before, but the work they’ve done with companies nothing like yours may be even more valuable. They will bring a different perspective to your design than what your in-house team will be able to conceptualize.

Cost Savings: The cost of change grows as the design process continues. It’s best to catch any obstacles or changes as early as possible so that it is less costly to make adjustments. With manufacturing engineering support, you are able to identify necessary changes early in the process.

Hidden Factories: The design process that involves manufacturing engineering support will expose what are referred to as hidden factories, or areas in which a process costs more money than is possible to extract in value.

Consolidation: Involving an engineer in your design process helps identify areas where parts or the process can be made more efficient without sacrificing performance. It may be that two parts can be combined into one or part of a process eliminated altogether to save costs.

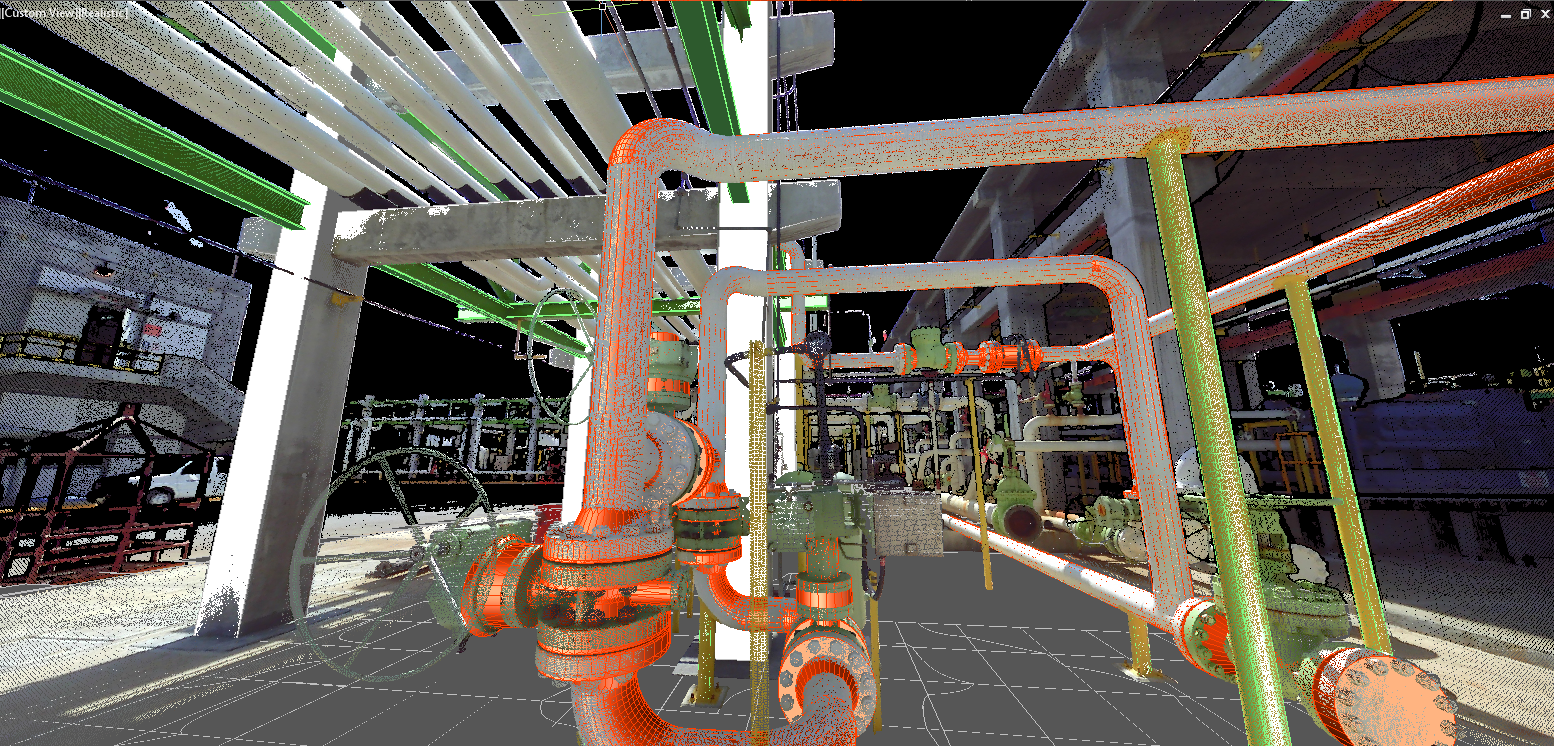

Analysis: You don’t need to wait until you have a prototype to determine your part needs additional design adjustments. With the right manufacturing engineering support, you will know where stress and strain are compromising your design.

Material Alternatives: A company may design a part or process according to a design they have seen or worked with, but an engineer can make recommendations about an alternative or substitute material that may work better or may enable them to cut costs.

Expertise: Generally speaking, most companies don’t work with manufacturing design on a daily basis, but a specialty engineering firm uses the technology and techniques on a daily basis. They are going to be more familiar with particular challenges and be able to anticipate obstacles that could be present in the design.

Is your company starting a manufacturing design process? Contact us at Finite Engineering, and let’s talk through your design and how we can help you save time and costs in your development process.

Helpful Resources

Contact Us

Quick Links

Finite Engineering Associates 3D, LLC. All Rights Reserved.